Cut Resistant Gloves Explained: Levels A1–A9 Safety Standards

Learn how cut resistant gloves protect workers from sharp edges and dangerous materials.

This guide explains ANSI/ISEA levels A1–A9, compares materials, and helps you choose

the right gloves for your industry.

What are Cut Resistant Gloves?

Cut resistant gloves are safety gloves designed to provide different levels of protection against sharp edges.

They are commonly made from advanced fibers and blends, which balance safety and dexterity:

- HPPE (High-Performance Polyethylene) – lightweight and strong.

- Kevlar® – durable, heat-resistant, and widely used.

- Stainless Steel Yarn – maximum protection for heavy-duty use.

- Glass Fiber Blends – reliable protection in composite gloves.

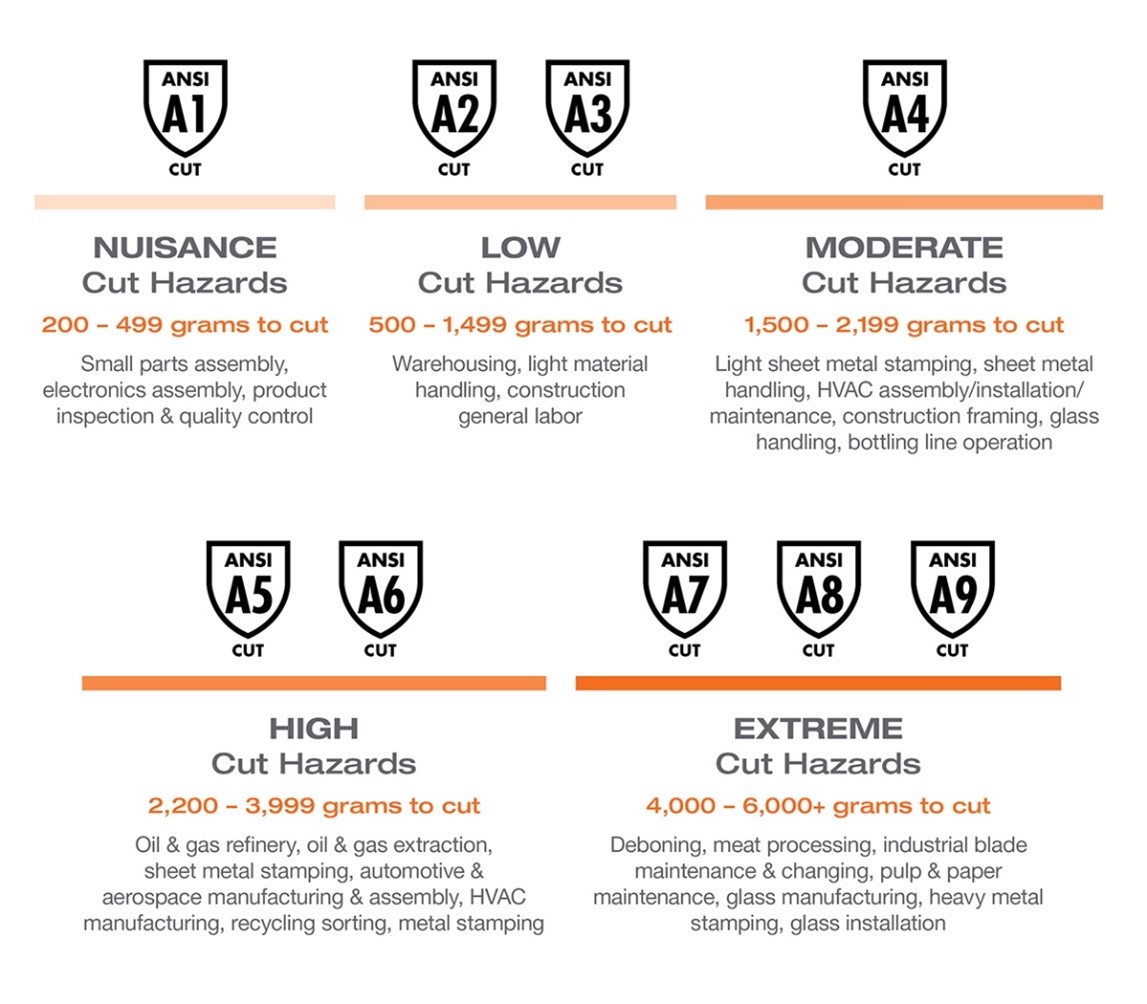

ANSI/ISEA Cut Resistance Levels (A1–A9)

In the US, cut resistance is measured by the

ANSI/ISEA 105 Standard.

Gloves are rated from A1 (light protection) to A9 (maximum protection).

| Level | Grams to Cut | Best For |

|---|---|---|

| A1 – A3 | 200 – 999 | Packaging, food service, light assembly |

| A4 – A6 | 1000 – 2999 | Construction, sheet metal, automotive |

| A7 – A9 | 3000+ | Steelwork, glass manufacturing, heavy-duty tasks |

Real-World Examples of Cut Resistant Glove Use

Food Processing

Butchers and chefs use A5–A7 cut resistant gloves when slicing meat or filleting fish.

This helps prevent deep knife injuries in fast-paced kitchens.

Construction & Carpentry

Workers handling sheet metal, roofing materials, or sharp wood edges typically wear

A4–A5 gloves for a balance of safety and dexterity.

Glass Manufacturing

A7–A9 gloves are common when handling large panes of glass, reducing the risk of

severe cuts from sharp, heavy materials.

Automotive & Metalwork

Mechanics and factory workers use A3–A6 gloves to safely handle sharp car parts,

stamping equipment, and sheet metal.

Tactical & Emergency Services

Law enforcement and rescue workers often wear cut resistant gloves for protection

when dealing with broken glass or knives.

Breaking Down the Levels

A1–A3: Light Protection

Best for handling small tools, packaging, or food prep. Thin, flexible, and comfortable.

A4–A6: Medium Protection

Popular for construction, sheet metal, and glass handling. A balance of safety and dexterity.

A7–A9: Maximum Protection

Industrial-level gloves for extreme hazards like heavy machinery, steel cables, or glass cutting.

How to Choose the Right Gloves

- Match hazards: Select gloves rated for your task’s risk level.

- Comfort & Fit: Gloves should fit snugly without reducing mobility.

- Dexterity: Higher protection can mean thicker gloves — balance is key.

- Environment: Some jobs require chemical, heat, or oil resistance too.

Not sure about your size? See our Glove Sizing Guide.

Safety Standards & Compliance

Employers in the US must follow

OSHA safety requirements.

ANSI/ISEA 105 provides cut resistance testing in North America, while Europe uses the EN 388 Standard.

Always check your gloves meet the required certification for your region.

FAQs About Cut Resistant Gloves

Do cut resistant gloves stop all cuts?

No, they reduce risk but don’t make hands 100% cut-proof, especially against punctures or extreme force.

ANSI vs EN ratings – what’s the difference?

ANSI/ISEA 105 uses A1–A9 levels. EN 388 uses a numeric code system covering abrasion, cuts, tears, and punctures.

Should I buy A9 gloves for every job?

No. A9 gloves are bulky and not necessary for most tasks. Choose the lowest rating that safely covers your risks.

Pro Tip: For most construction and metal work, A4–A5 gloves provide the best balance of protection and comfort.